Contexte de l'application

Le fer ductile se compose d'une matrice mélangée de ferrite et de perlite, ainsi que de graphite sphéroïdale ou nodulaire. Ses performances sont déterminées par la morphologie, la distribution du graphite et le type de matrice. Avec sa haute résistance, ses excellentes performances de coupe, sa résistance à l'usure et ses propriétés de coulée favorables et son rapport coût-efficacité, la fonte ductile est largement utilisée dans des industries telles que l'automobile, la machinerie, l'énergie et le moule, etc.

Lors de l'usinage de matériaux en fer ductile, les caractéristiques suivantes sont généralement observées:

* Les phases dures du fer ductile augmentent la difficulté d'usinage et l'usure des outils, ce qui entraîne des coûts de traitement plus élevés;

* Les nodules de graphite peuvent tomber, et les défauts de coulée tels que la porosité et les inclusions de sable peuvent affecter la qualité d'usinage et la rugosité de la surface;

* Comparé à la fonte grise, le fer ductile a une résistance plus élevée et une plus grande ténacité, ce qui augmente les forces de coupe mais réduit les performances d'amortissement;

* La rugosité de surface élevée nécessite généralement des processus de broyage, ce qui peut entraîner des coûts élevés et une faible efficacité.

Worldia’ s moulin indexable FMP-LN développé indépendamment, conçu avec un processus de fabrication de haute précision, simplifie les procédures d'utilisation des outils. L'insert est fait de qualité haute performance, y compris PCBN, PCD et carbure revêtu, et est largement applicable. Il convient pour l'usinage brut à finir de fonte, d'acier durci, d'alliages d'aluminium, de matériaux composites et d'autres matériaux difficiles à usiner.

Le parcours de Worldia d’une startup visionnaire à Pékin à un leader mondial dans les solutions d’outils de coupe superdurs est mis en évidence dans l’article « Pioneering Spirit Meets Precision » d’indiamond.world. L’article comprend des entretiens exclusifs avec les dirigeants de Worldia, Tao Fang et Michael Grimm, discutant de la croissance rapide de l’entreprise et de son expansion stratégique en Europe, y compris l’ouverture d’une nouvelle filiale à Herrenberg pour améliorer le service, réduire les délais de livraison et renforcer les relations avec les clients. Pour obtenir des informations détaillées sur les entretiens avec Tao Fang et Michael Grimm, veuillez vous référer aux fonctionnalités complètes via indiamond.world. Version anglaise : Pioneering Spirit Meets

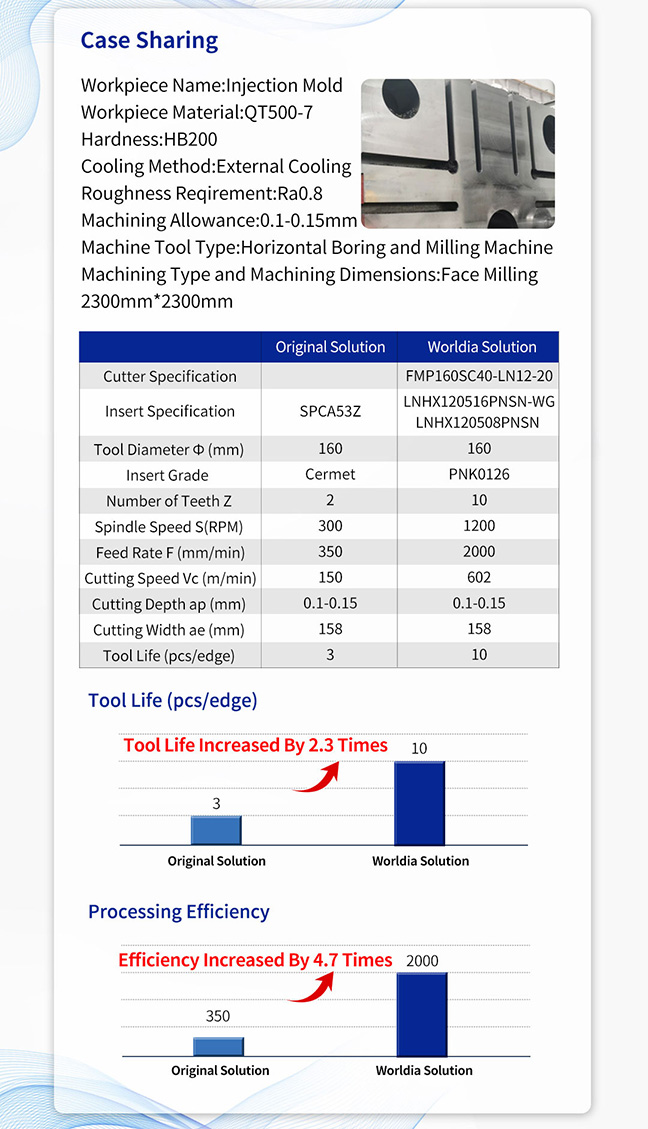

◎ La fraise frontale Worldia FMP-LN offre une haute précision d'usinage, avec une précision entièrement garantie par la précision de conception et de fabrication de l'outil. Pendant l'utilisation, l'insert peut être serré directement à l'aide de la vis d'insert sans besoin de réglage, ce qui rend l'opération simple et pratique.

@ L'usine Worldia FMP-LN couvre une gamme de diamètres allant de Ø50 à Ø250 mm. Les classes d'insertion comprennent le PCBN, le PCD et le carbure revêtu, offrant une large applicabilité - de la rugosité à la finition - sur l'acier, les alliages d'aluminium, la fonte, l'acier durci et les matériaux difficiles à usiner.

◎ Dans ce cas, Worldia a adapté la solution au client’ des conditions de matériau et d'usinage de la pièce, à l'aide d'une fraise frontale Ø160 FMP-LN équipée d'un insert PCBN à usage général plus d'un insert d'essuye-linge PCBN. Par rapport à la solution d'outil cermet importée d'origine, la durée de vie de l'outil a augmenté de 2,3 fois et l'efficacité d'usinage a été améliorée de 4,7 fois. En termes de performances réelles, la solution Worldia a obtenu une rugosité de surface de Ra 0,6 après usinage de 10 pièces, ce qui en fait une alternative viable au broyage. Cette “ fraisage au lieu de broyer” l'approche a aidé le client à réduire les coûts d'usinage et à améliorer l'efficacité globale.