응용 프로그램 배경

연성 철은 페라이트와 진주석의 혼합 매트릭스와 구형 또는 결점형 그라이트로 구성되어 있습니다.성능은 형태학, 그라파이트의 분포 및 매트릭스의 유형에 의해 결정됩니다.고강도, 우수한 절단 성능, 내마모성 및 유리한 주조 특성과 비용 효율성으로 연성 주철은 자동차, 기계, 에너지 및 금형 등과 같은 산업에서 널리 사용됩니다.

연성 철 재료를 가공할 때 다음 특성은 일반적으로 관찰됩니다.

* 연성 철의 단단한 단계는 더 높은 가공 비용으로 이어지는 가공 어려움과 도구 마모를 증가시킵니다;

* 그래파이트 노드는 떨어질 수 있으며, 공공성과 모래 포함과 같은 주조 결함은 가공 품질과 표면 거친도에 영향을 미칠 수 있습니다;

* 회색 주철과 비교하면, 연성 철은 절단 힘을 증가시키지만 감소 성능을 줄이는 더 높은 강도와 더 큰 견고성을 가지고 있습니다;

* 높은 표면 거친도는 일반적으로 높은 비용과 낮은 효율성으로 이어질 수 있는 연磨 공정을 필요로합니다.

Worldia’고정밀 제조 프로세스로 설계된 독립적으로 개발된 FMP-LN 인고고독 가능한 밀은 도구 사용 절차를 단순화합니다.인서트는 PCBN, PCD 및 코팅된 탄화물을 포함한 고성능 급료로 만들어져 있으며 광범위하게 적용 가능합니다.그것은 주철, 강화된 강철, 알루미늄 합금, 복합 재료 및 기계에 어려운 다른 재료의 가공을 완료하는 데 적합합니다.

파이오니어링 프리시전: 유럽의 월드리아의 전략적 경로 베이징의 비전적인 스타트업에서 슈퍼하드 절단 도구 솔루션의 글로벌 리더로 이어진 월드리아의 여정은 indiamond.world의 기사 "파이오니어링 스피리트 미트 프리시전"에서 강조되어 있습니다.이 작품은 Worldia의 리더인 Tao Fang과 Michael Grimm과 독점적인 인터뷰를 통해 회사의 빠른 성장과 전략적 확장에 대해 논의하고 있으며, 서비스를 향상시키고 리드 타임을 줄이고 고객 관계를 강화하기 위해 Herrenberg에 새로운 자회사를 개설하는 것을 포함합니다.Tao Fang과 Michael Grimm과의 인터뷰에서 자세한 통찰력을 얻으려면 indiamond.world에서 전체 기능을 참조하십시오.영어 버전: Pioneering Spirit Meets

◎ Worldia FMP-LN 페이스 밀링 커터는 도구의 자체 설계 및 제조 정확도로 완전히 보장되는 높은 가공 정확도를 제공합니다.사용 중에 인서트는 조정 필요없이 인서트 나사를 사용하여 직접 클램프 할 수 있으며 작동을 간단하고 편리하게 합니다.

@ Worldia FMP-LN 밀은 Ø50에서 Ø250 mm까지의 직경 범위를 다루고 있습니다. 인서트 그레이드는 PCBN, PCD 및 코팅된 탄화물을 포함하여 강철, 알루미늄 합금, 주철, 경화된 강철 및 기계화하기 어려운 재료에 대한 광범위한 적용 가능성을 제공합니다.

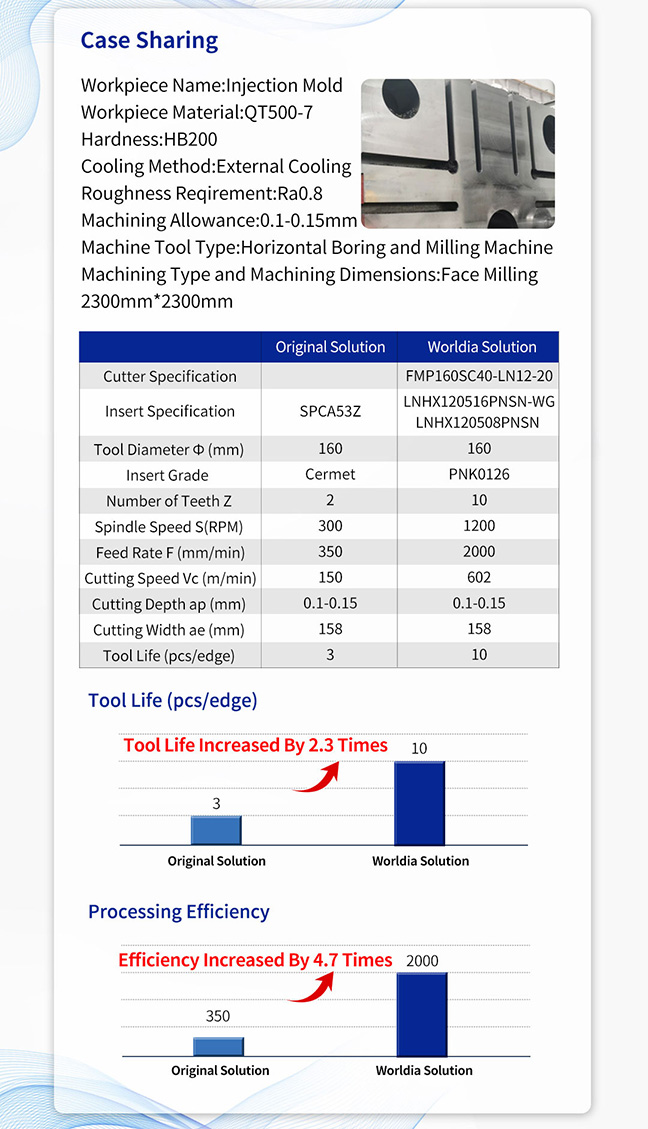

◎ 이 경우 Worldia는 고객’에 맞춤형 솔루션을 제공했습니다.일반용 PCBN 인서트와 PCBN 와이퍼 인서트가 장착된 Ø160 FMP-LN 페이스 밀링 커터를 사용하여 작품 재료 및 가공 조건.원래 수입된 cermet 도구 솔루션과 비교하면 도구 수명이 2.3배 증가했으며 가공 효율성이 4.7배 증가했습니다.실제 성능에서 Worldia 솔루션은 10 개의 부품을 가공한 후 Ra 0.6의 표면 거실실실성을 달성했으며, 연磨에 대한 실현가능한 대안으로 만들었습니다.이 “가공 대신 가공”접근 방식은 고객이 가공 비용을 줄이고 전반적인 효율성을 향상시킬 수 있도록 도왔습니다.