Tło aplikacji

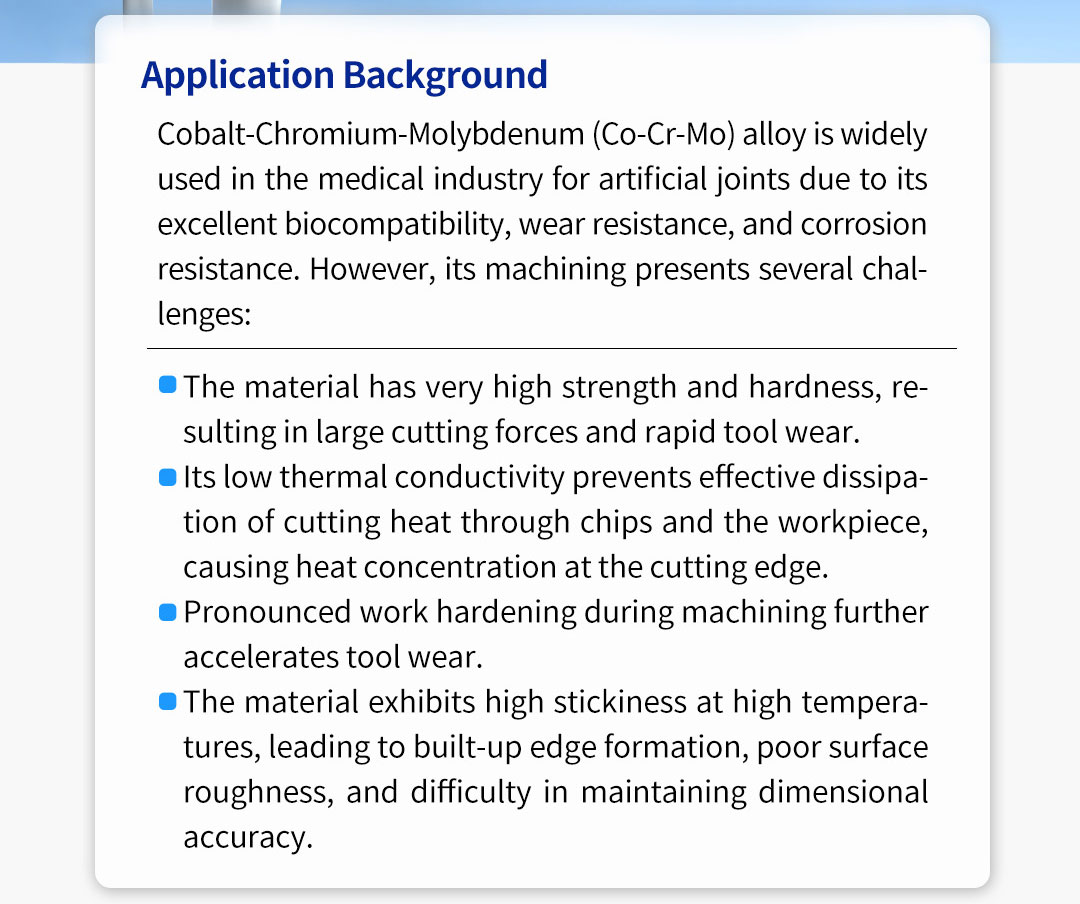

Stop kobaltu-chromu-molibdenu (Co-Cr-Mo) jest szeroko stosowany w przemyśle medycznym do sztucznych stawów ze względu na doskonałą biokompatybilność, odporność na zużycie i odporność na korozję. Jednak jego obróbka stanowi kilka wyzwań:

* Materiał ma bardzo wysoką wytrzymałość i twardość, co powoduje duże siły cięcia i szybkie zużycie narzędzia.

* Jego niska przewodność cieplna zapobiega skutecznemu rozpraszaniu ciepła cięciego przez wiórki i przedmiot obrabiany, powodując stężenie ciepła na krawędzi cięciej.

* Wyrażane utwardzanie podczas obróbki przyspiesza zużycie narzędzia.

* Materiał wykazuje wysoką lepkość w wysokich temperaturach, co prowadzi do tworzenia się zabudowanych krawędzi, słabej szorstkości powierzchni i trudności w utrzymaniu dokładności wymiarowej.

Funkcje rozwiązania

* W przypadku trudnych do obróbki materiałów w wyspecjalizowanych gałęziach przemysłu, dostosowane do potrzeb narzędzia Worldia mogą zapewnić wydajne i niezawodne rozwiązania obróbkowe.

W tym przypadku, na podstawie cech materiału Co-Cr-Mo i rzeczywistych warunków pracy, Worldia wybrała klasę PNS2007, która oferuje doskonałą odporność na zużycie i stabilność termiczną, w połączeniu ze specjalnie zaprojektowaną geometrią krawędzi cięciej. Pomagało to klientowi przedłużyć żywotność narzędzia, zmniejszyć częstotliwość zmiany narzędzia i poprawić wydajność obróbki.

* Praktyka udowodniła, że dzięki dostosowanym rozwiązaniom narzędziowym Worldia może pomóc klientom zmniejszyć koszty narzędzia i pomyślnie osiągnąć lokalizację narzędzi cięcich.