Fundo da aplicação

Blocos de motores bimetálicos (tipicamente blocos de liga de alumínio “ linha de ferro fundido”) são amplamente usados em motores automobilísticos modernos para equilibrar redução de peso e resistência ao uso. Contudo, boros de cilindros de motor bimetal chatos apresentam os seguintes desafios de máquina:

* Ligação de alumínio chata na entrada do boro é propensa a produzir bordo construído, levando a desvios dimensionais e qualidade de máquina inconsistente;

* O boro de linha de ferro casteado requer alta precisão dimensional, tolerâncias de forma apertada, e excelente terminação da superfície;

* Existe uma demand a de longa vida de ferramentas e alta eficiência máquinaria.

Como parceiro confiável, a Worldia oferece soluções personalizadas de ferramentas PCBN para lidar com desafios e necessidades de máquina dos clientes. Essas soluções ajudam a melhorar a produtividade e reduzir os custos de máquina para operações de borragem de motores bimetais.

Fundo da aplicação

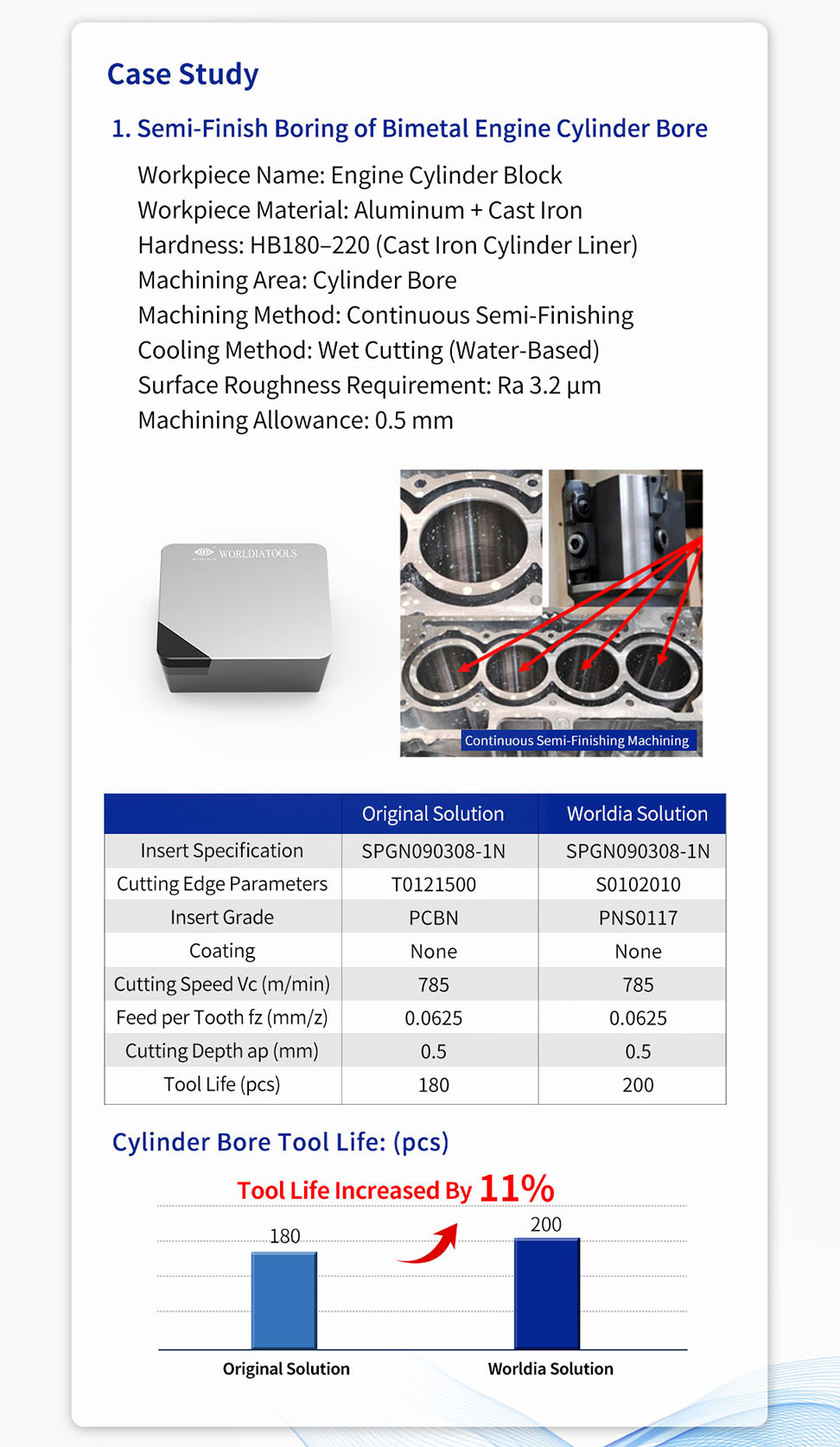

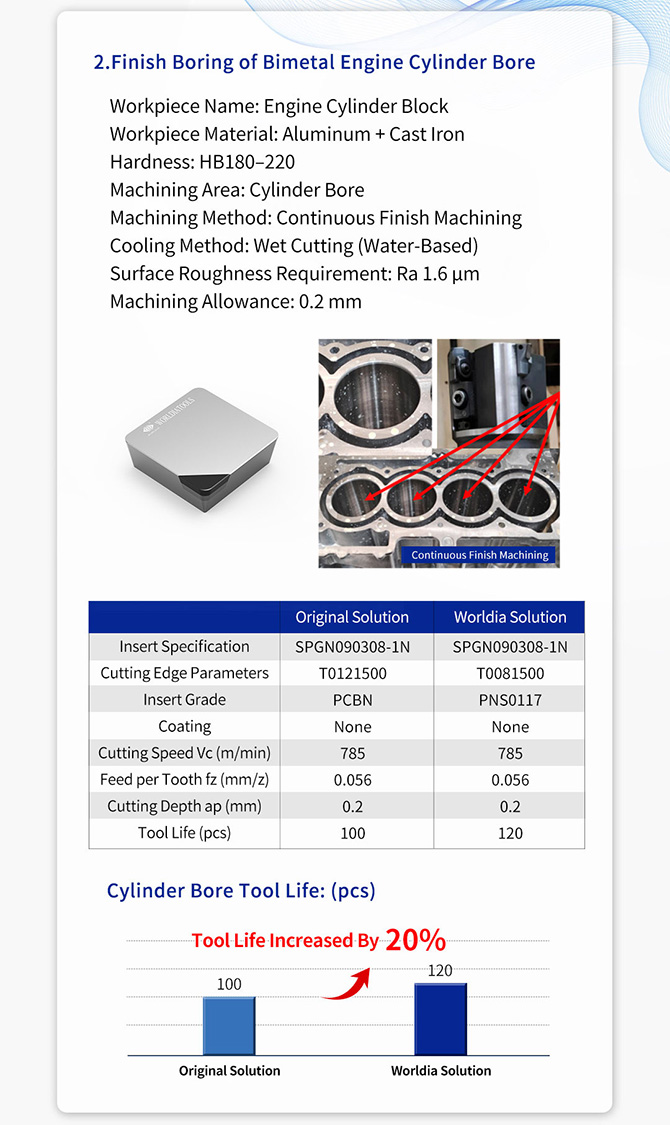

Com base nas licenças de semiterminação e terminação e condições de corte do cliente, a solução da Worldia adota inserimentos de microbordo especialmente projetados para reduzir a formação de bordo construído na entrada do boro, assegurando precisão máquinaria e qualidade da superfície.

A inserção utilizada na solução Worldia é feita de guarda PNS0117, um grau de alto conteúdo CBN que oferece excelente resistência ao chipping e excelente estabilidade química, o que ajuda a alcançar uma vida mais longa de ferramentas.

Comparado com a solução original, a solução de ferramentas PCBN personalizada da Worldia melhorou significativamente a vida de ferramentas tanto em semi-finição como na finição do boro de cilindro. Reduziu mudanças de ferramentas e tempo de descanso, melhorou a eficiência da máquina e reduziu os custos globais de processamento para o cliente.