Uygulama Arka planı

Kılavuz yastıkları olan aletler özel deliklerin hassas işlenmesi için çok uygundur. Mükemmel işleme doğruluğu ve yüzey bitirmesini sağlarken yüksek verimlilik ve istikrar sunarlar. Uygulamaları, otomotiv motor valfı kılavuz delikleri, krank mili delikleri, cam mili delikleri, inşaat makinelerindeki hassas hidrolik valf delikleri ve kalıp imalatı endüstrisindeki kılavuz kol delikleri de dahil olmak üzere birçok endüstriyi kapsar.

Bu tür bileşenler genellikle delik açma sırasında aşağıdaki özel koşullarla karşılaşırlar:

————————————————————————————————————————-

* Sıkı yuvarlaklık ve silindirlik toleransları gerektiren yüksek uzunluk-çap oranlarına sahip derin delikler;

* Yüksek yüzey kalitesi gereksinimleri ile kısmen delikler bitirme;

* Ve sıkı konumlu tolerans gereksinimleri ile adımlanmış veya kesilmiş delikler.

Bu vaka çalışmasında, Worldia'nın kılavuz yastıkları ile PCBN reamer, inşaat makinelerindeki hidrolik valf deliklerinin işlenmesine uygulandı. Bu alet sadece alet ömrünü önemli ölçüde uzattı ve zaman alıcı alet ayarlarının sıklığını azaltmadı, aynı zamanda ithal edilen kesme aletlerinin yerli değiştirilmesini de elde etti - maliyetleri etkili bir şekilde azalttı ve müşteri için verimliliği arttırdı.

Çözüm Analizi

◎ Worldia'nın özelleştirilmiş süper sert aletleri, müşterilere özel deliklerle işlenmesi zor malzemeler ve bileşenler için özel işleme çözümleri sağlayabilir.

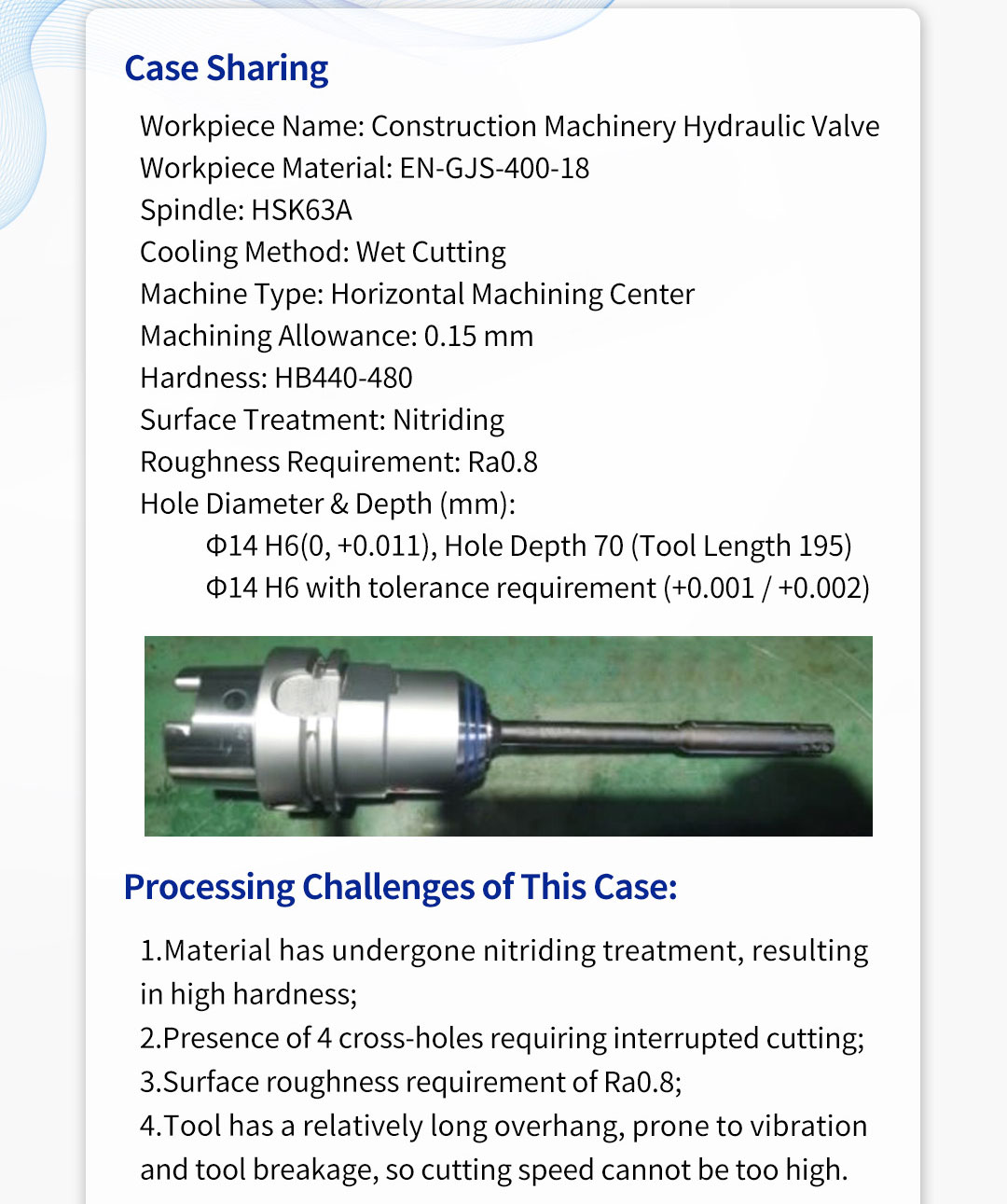

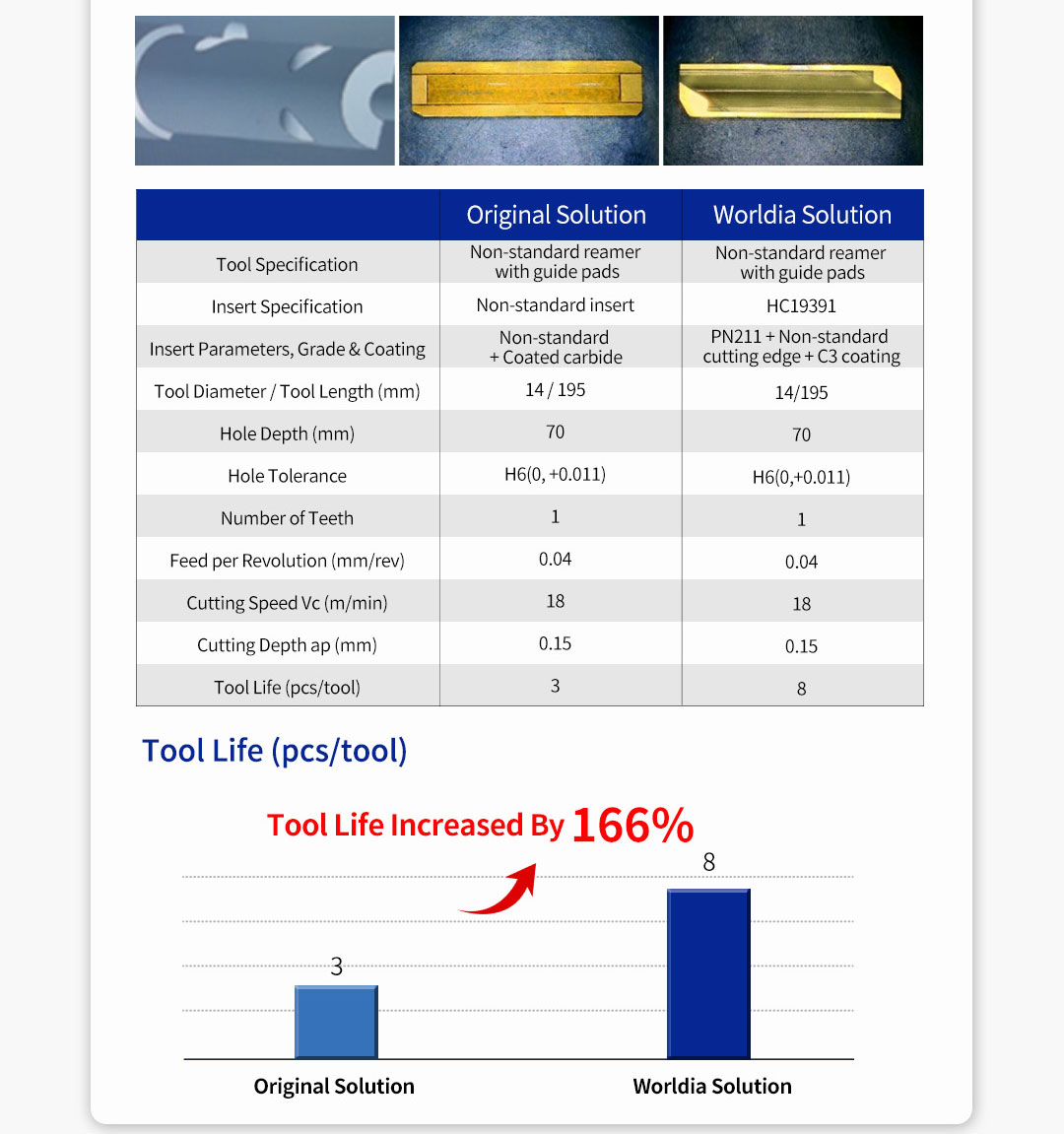

◎ Bu durumda, Worldia'nın PCBN takımları ile özelleştirilmiş kılavuz yastıkları aracı, müşterinin malzeme özelliklerine, gerçek işleme koşullarına ve süreç gereksinimlerine dayanarak tasarlanmıştır. Dikkatli bir şekilde seçilmiş bir PCBN sınıfını kullanır, özel kesim kenarı parametreleri ve kenar mukavemetini arttıran C3 kaplaması ile birleştirilir ve müşterinin alet ömründe% 166 artış elde etmesine yardımcı olur.

◎ Orijinal ithal edilen takım çözümüyle karşılaştırıldığında, Worldia'nın özelleştirilmiş PCBN takımı sadece takım ömrünü uzatmakla kalmaz, aynı zamanda üstün delik boyut doğruluğu ve işleme kalitesi de sağlar. Ayrıca, karmaşık rehber yastıklarının alet ayarlarının ve makine durma süresinin frekansını etkili bir şekilde azaltır, operatör emek yoğunluğunu azaltır, işleme verimliliğini arttırır ve müşterinin ithal edilen kesme aletlerinin yerelleştirilmiş değiştirilmesine yardımcı olur.

◎ Son yıllarda, yerli kobalt ve tungsten hammaddelerinin fiyatlarının sürekli artmasıyla, yüksek performanslı süper sert alet çözümleri yavaş yavaş yüksek maliyetli ithal alaşımlı aletlerin yerini alıyor ve kaçınılmaz bir gelişme eğilimi haline geldi.