Anwendungshintergrund

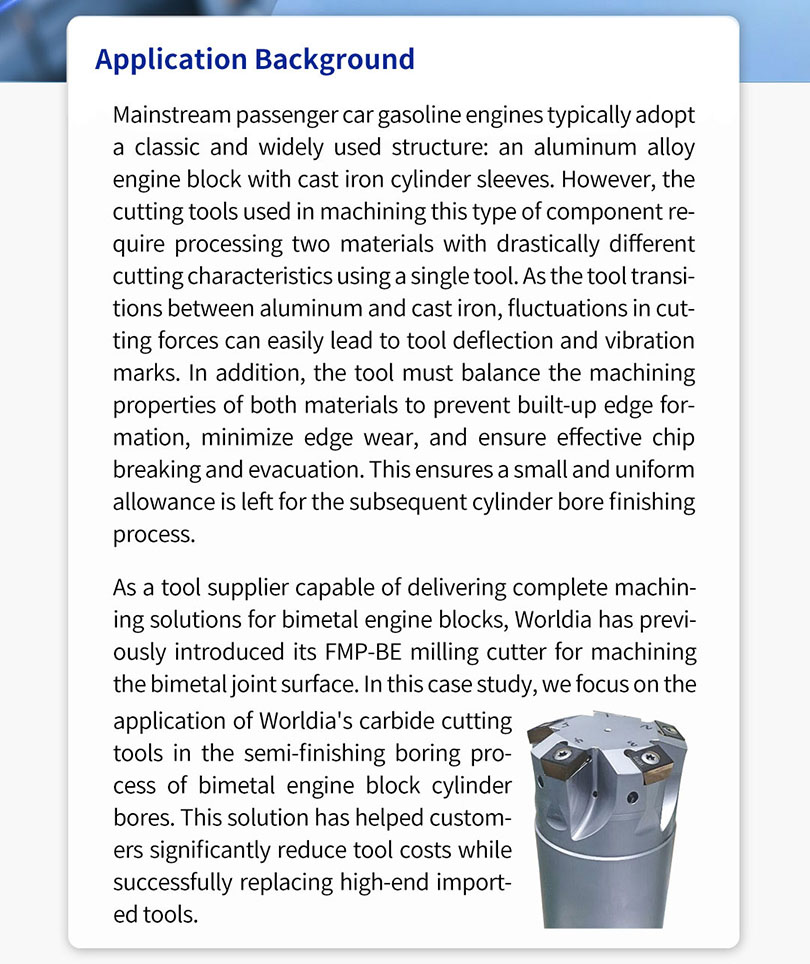

Mainstream-Pkw-Benzinmotoren nehmen in der Regel eine klassische und weit verbreitete Struktur an: einen Aluminiumlegierungsmotorblock mit Gusseisen-Zylinderhülsen. Die bei der Bearbeitung dieses Bauteils verwendeten Schneidwerkzeuge erfordern jedoch die Bearbeitung von zwei Materialien mit drastisch unterschiedlichen Schneideigenschaften mit einem einzigen Werkzeug. Während das Werkzeug zwischen Aluminium und Gusseisen übergeht, können Schwankungen der Schneidkräfte leicht zu Werkzeugauslenkungen und Vibrationsmarken führen. Darüber hinaus muss das Werkzeug die Bearbeitungseigenschaften beider Materialien ausgleichen, um eine aufgebaute Kantenbildung zu verhindern, Kantenbeschleiß zu minimieren und effektives Spanbrechen und Evakuierung zu gewährleisten. Dies gewährleistet, dass für den anschließenden Zylinderbohrungsverarbeitungsprozess eine kleine und gleichmäßige Zulassung übrig bleibt.

Als Werkzeuglieferant, der komplette Bearbeitungslösungen für Bimetall-Motorblöcke anbieten kann, hat Worldia bereits seinen Fräser FMP-BE zur Bearbeitung der Bimetall-Gelenkfläche eingeführt. In dieser Fallstudie konzentrieren wir uns auf die Anwendung der Karbidschneidwerkzeuge von Worldia im Halbfertigungsbohrprozess von Bimetall-Motorblock-Zylinderbohrungen. Diese Lösung hat den Kunden geholfen, die Werkzeugkosten erheblich zu senken und gleichzeitig erfolgreich importierte High-End-Werkzeuge zu ersetzen.

Lösungsanalyse

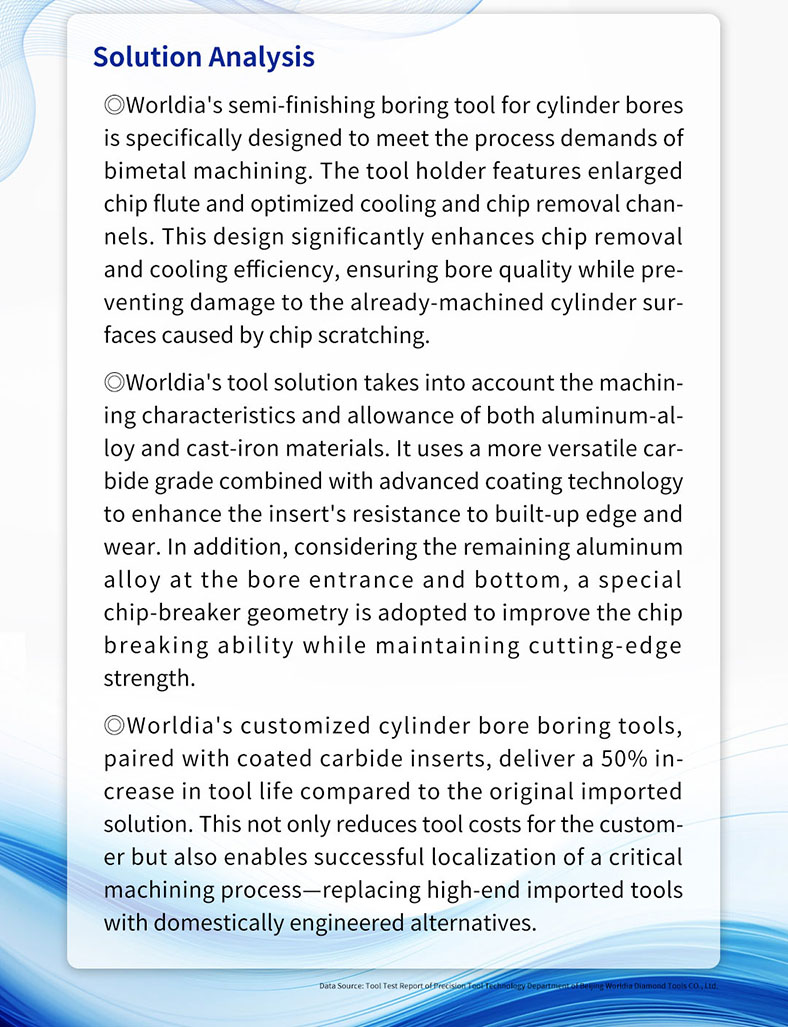

* Das Halbfertigungsbohrwerkzeug für Zylinderbohrungen von Worldia ist speziell entwickelt, um den Prozessanforderungen der Bimetallbearbeitung gerecht zu werden. Der Werkzeughalter verfügt über vergrößerte Spanflöte und optimierte Kühl- und Spanentfernungskanäle. Diese Konstruktion verbessert die Spänentfernung und die Kühleffizienz erheblich, gewährleistet die Bohrungsqualität und verhindert Schäden an den bereits bearbeiteten Zylinderoberflächen, die durch Spänkratzen verursacht werden.

* Die Werkzeuglösung von Worldia berücksichtigt die Bearbeitungseigenschaften und den Anteil von Aluminium- und Gusseisen-Materialien. Es verwendet eine vielseitigere Karbidqualität in Kombination mit fortgeschrittener Beschichtungstechnologie, um die Beständigkeit des Einsatzes gegen aufgebaute Kanten und Verschleiß zu erhöhen. Darüber hinaus wird unter Berücksichtigung der verbleibenden Aluminiumlegierung am Bohreingang und Boden eine spezielle Spanbrechergeometrie angenommen, um die Spanbrechfähigkeit zu verbessern und gleichzeitig die Spitzenfestigkeit zu erhalten.

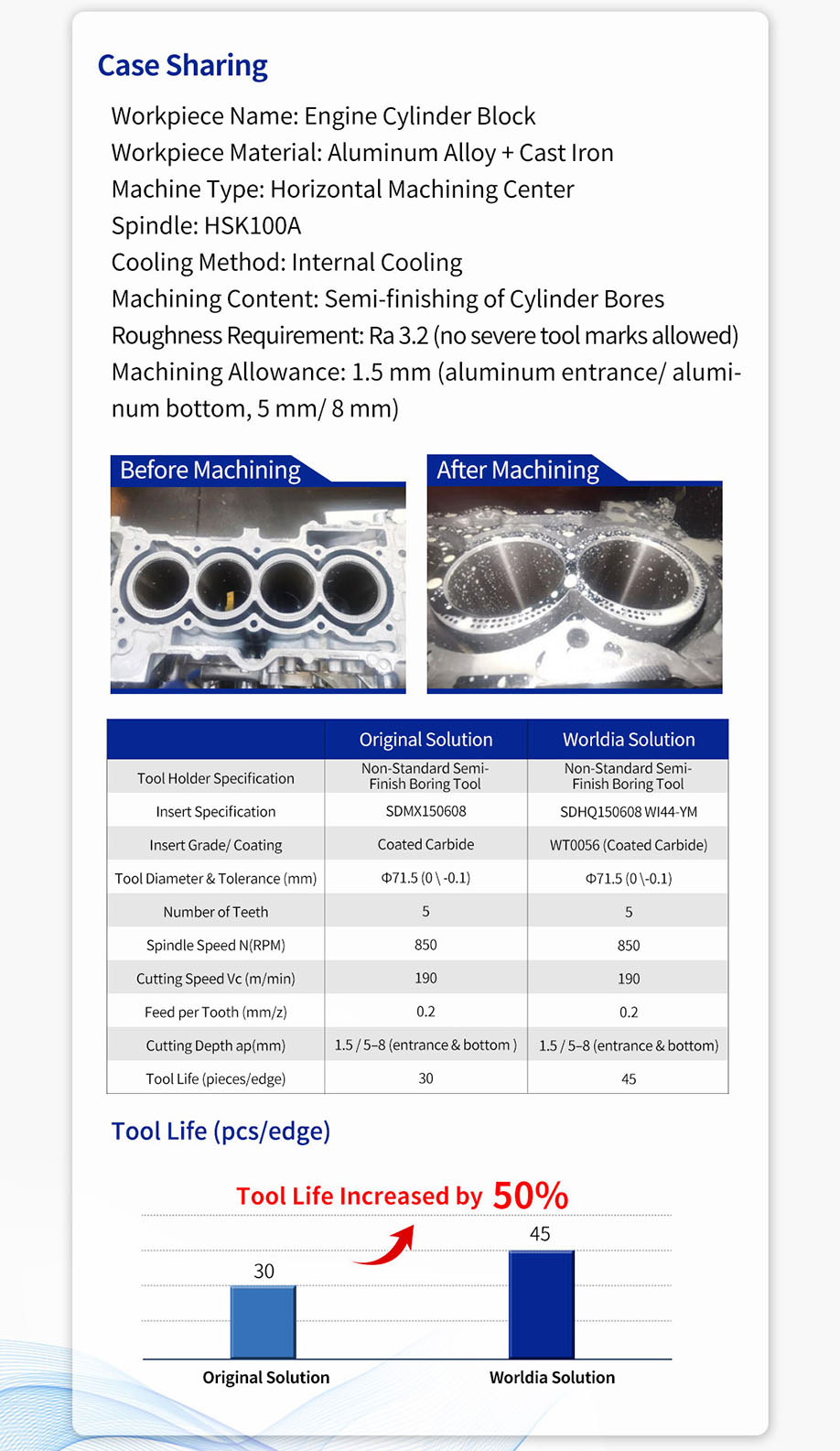

* Worldias maßgeschneiderte Zylinderbohrungswerkzeuge, gepaart mit beschichteten Karbideinsätzen, erhöhen die Werkzeuglebensdauer um 50% im Vergleich zur ursprünglichen importierten Lösung. Dies reduziert nicht nur die Werkzeugkosten für den Kunden, sondern ermöglicht auch die erfolgreiche Lokalisierung eines kritischen Bearbeitungsprozesses – High-End-importierte Werkzeuge werden durch inländische Alternativen ersetzt.