Antecedentes de la aplicación

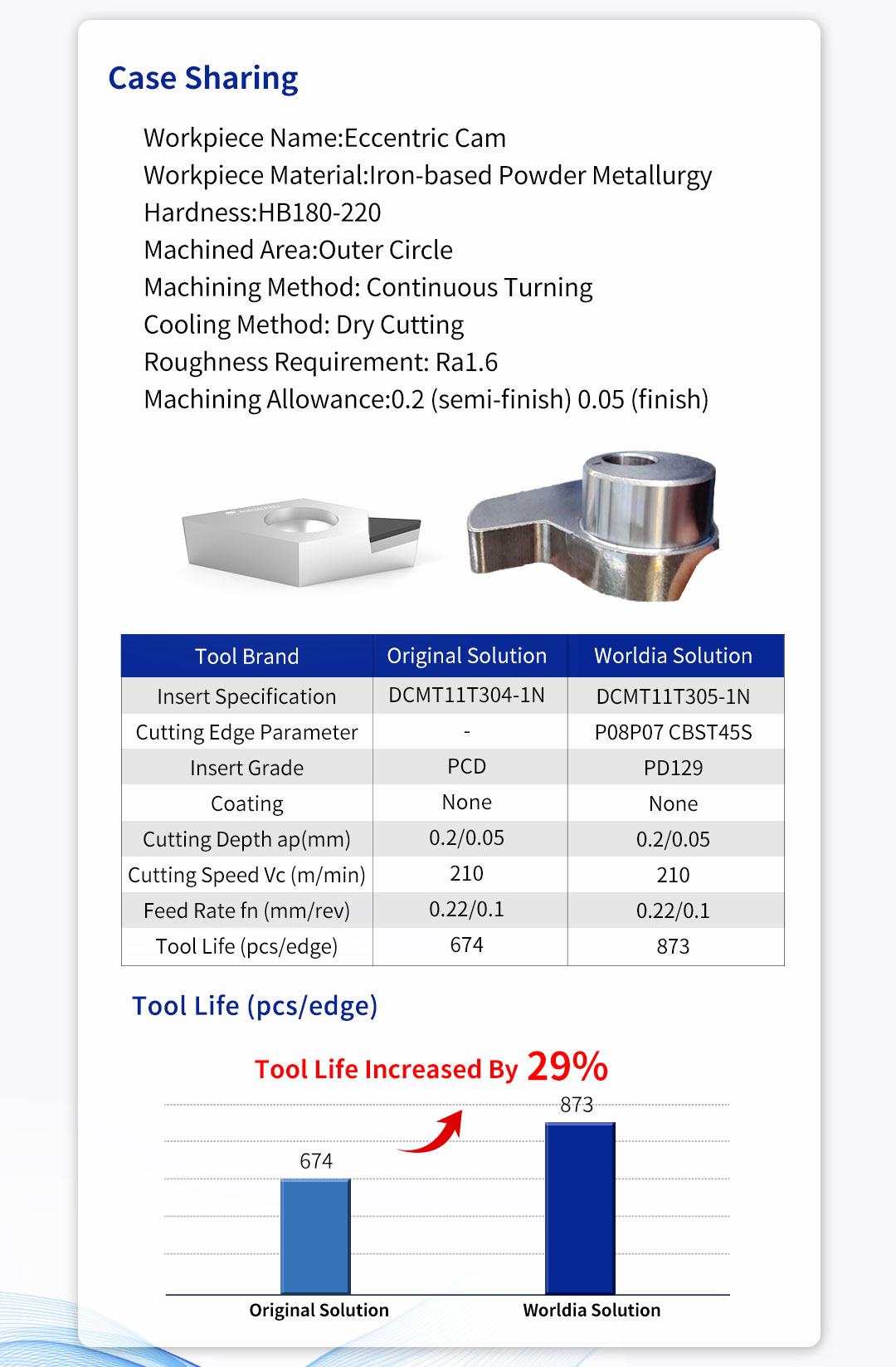

Los materiales de metalurgia de polvo son ampliamente utilizados debido a sus características tales como diversos tipos, flexibilidad de diseño, alta tasa de utilización de materiales y preparación de materiales especiales, y sus productos cubren numerosos campos industriales. Este caso demuestra que los insertos PCD personalizados de Worldia han reemplazado con éxito los insertos PCD de otras marcas para el torneo de semi-acabado a acabado de componentes excéntricos de leva de metalurgia de polvo a base de hierro, ayudando a los clientes a prolongar la vida útil de la herramienta, reducir la frecuencia de cambio de herramienta y aumentar la eficiencia de producción de piezas bajo los mismos parámetros de corte.

Análisis de Solución

◎ En este caso, el material de metalurgia en polvo a base de hierro presenta una alta dureza y textura desigual, lo que tiende a causar fluctuaciones de la fuerza de corte durante el torneo, lo que conduce al rápido desgaste de la herramienta y a una mala calidad de mecanizado;

◎ Según el cliente’ Las condiciones de trabajo reales y las características materiales de las piezas, Worldia personalizado PCD insertos adoptan grado PD129 con resistencia al desgaste y tenacidad, y cuentan con un diseño especial de ángulo de borde de corte en combinación con la profundidad de corte requisitos para semiacabado y acabado, así como condiciones de corte seco. En comparación con la solución de herramienta original, la vida útil de la herramienta se ha aumentado en un 29%;

◎ Las herramientas superduras personalizadas de Worldia proporcionan a los clientes soluciones de herramientas dedicadas. En comparación con la solución original, prolongan la vida útil de la herramienta, reducen la frecuencia de cambio de herramienta y el tiempo de inactividad, aumentan la tasa de utilización de la máquina y ayudan a los clientes a mejorar la competitividad del producto en la feroz competencia del mercado.