In recent years, the domestic new energy vehicle (NEV) industry has developed rapidly. Whether it is pure electric vehicles, range-extended vehicles, or hybrid vehicles, all these models rely (either fully or partially) on converting electrical energy into mechanical energy to drive the wheels. As a critical component in this energy conversion process, the motor has garnered significant attention, particularly its motor housing. The machining processes and precision required for motor housings have been a key focus for tool manufacturers.

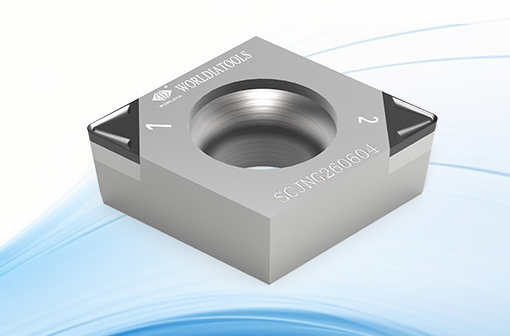

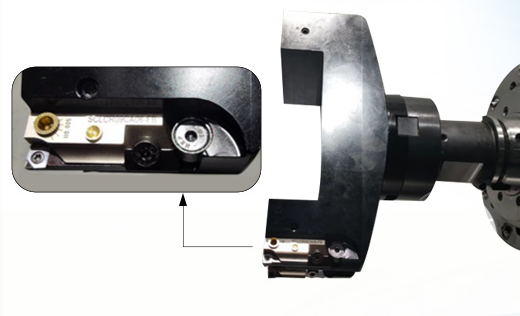

We showcase a case study involving Worldia’s meticulously designed and developed PCD (Polycrystalline Diamond) composite fine boring tool, used for machining the stator bore of motor housings.

(Data source: Test report on PCD composite precision boring tools by Beijing Worldia Diamond Tools Co., Ltd.)

Mit nur einem Klick gelangen Sie zum nächsten Thema.