The joint surfaces of automobile engine oil pan, gearbox oil pan and timing chain cover are processed with mesh to increase the contact surface and adhesion of sealant to prevent oil leakage.

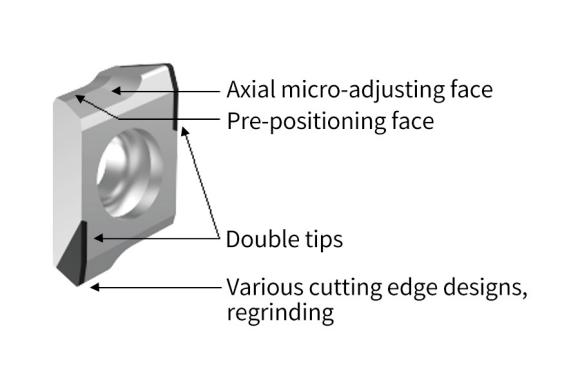

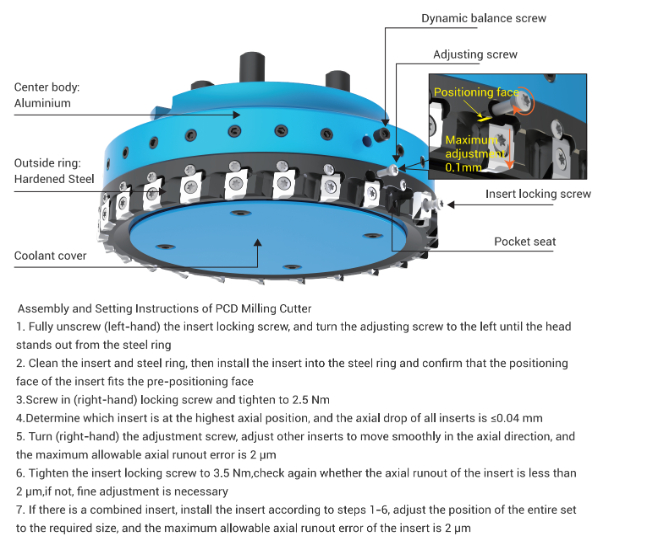

In this case, Worldia’s FMP-BE face milling cutter installs two milling inserts with different tip designs to leave cutting marks and return marks on the workpiece surface during the cutting process. Specially selected cutting parameters are used to control the size and depth of the marks, thereby obtaining a diamond-shaped mark that meets the requirements.

FMP-BE milling cutter is a milling cutter product developed by Worldia with independent intellectual property rights. The product series includes Ф25 and Ф32 end mills, Ф40 ~ Ф250 sleeve mills and Ф100 ~ Ф200 disc mills (two-sided and three-sided cutting edges). By selecting inserts with different main deflection angles, it can meet the needs of face milling, shoulder milling and slot milling. The inserts are available in a variety of materials, different cutting edge forms and different cutting edge designs for customers with different processing needs to choose from.

Mit nur einem Klick gelangen Sie zum nächsten Thema.