Application Background

As the positioning holes for installing camshaft plain bearings or bearing bushes, engine camshaft bores are a set of segmented coaxial bores. They have strict requirements on dimensional accuracy, geometric tolerance, and surface roughness, and serve as a crucial component to ensure the normal operation of the engine valve train. The machining tools for these bores, together with the crankshaft bore boring tools that share similar principles, form the processes in cylinder block and cylinder head production lines which feature high tool costs and great machining difficulty.

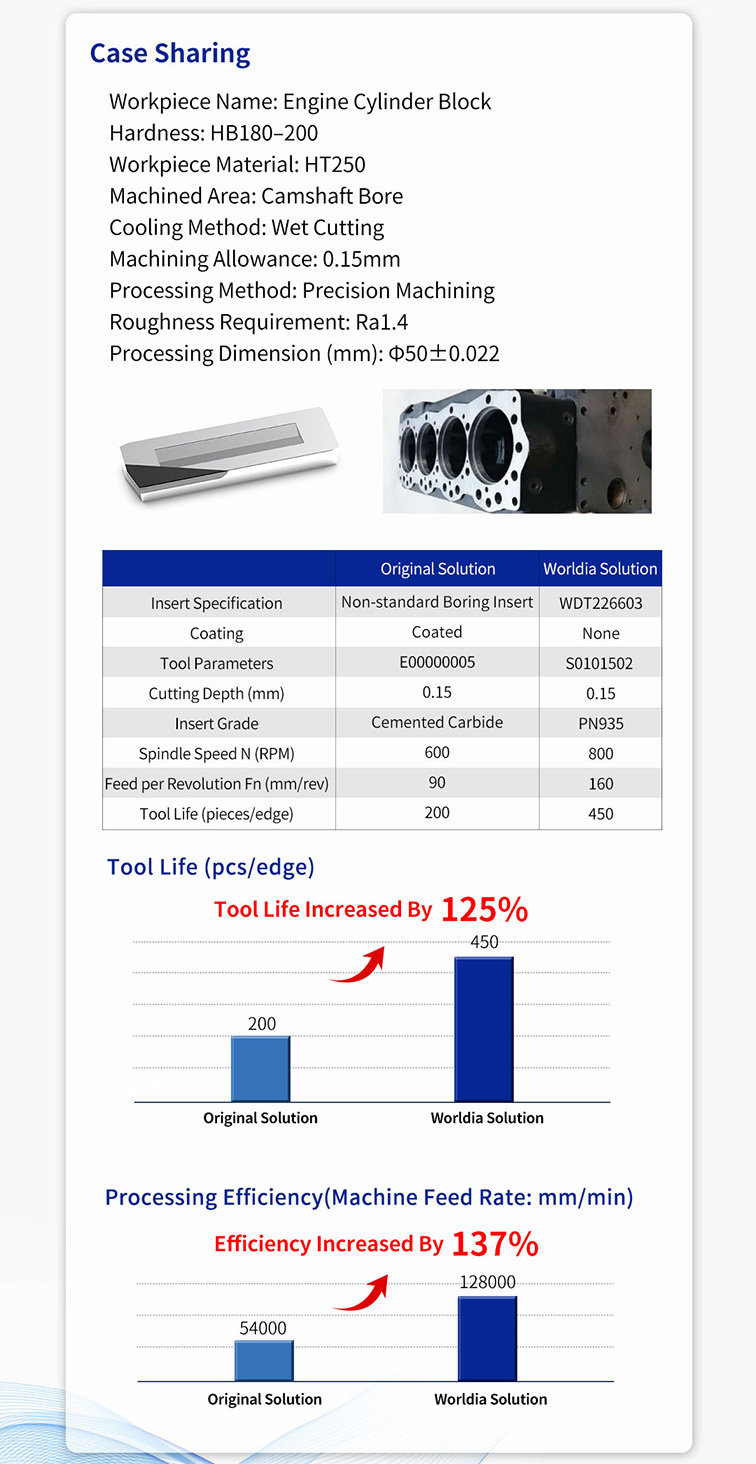

This case introduces how Worldia guide pads tool PCBN inserts have successfully replaced imported high-end alloy inserts. It has helped customers improve tool life and machining efficiency, reduce the cumbersome number of tool adjustments and downtime, lower machining costs, and enhance the competitiveness of their products.

Solution Analysis

◎Worldia’s customized PCBN boring inserts: Targeting the customer’s part material and process characteristics, the PN935 grade with excellent wear resistance was selected, and non-standard cutting edges were customized based on the machining allowance and actual working conditions. Compared with the customer’s original solution, the tool life has increased by 125%, and the machining efficiency has improved by 137%.

◎For the camshaft bore guide pads boring tool, the machine must be stopped to replace the insert and re-adjust the tool every time the tool is changed. The process is cumbersome and has high requirements for operational professionalism. Relying on longer tool life, Worldia’s solution significantly reduces the frequency of machine downtime and tool adjustments, saving labor costs and time costs for the customer.

◎Compared with the original imported non-standard tool solution, Worldia’s tools have a shorter delivery cycle, longer service life, higher machining efficiency and better cost performance. This helps customers enhance product competitiveness and successfully realize the replacement of expensive imported alloy tools with high-end domestic super-hard tools.