Application Background

Wind turbine gears are the core transmission components of gearboxes in wind turbine generators. The main function of a wind turbine gearbox is speed increase: it converts the low-speed, high-torque rotation captured by wind turbine blades into the high-speed, low-torque rotation required by generators. Under its unique operating conditions, wind turbine gears bear enormous fluctuating torque, coupled with continuously changing radial forces, axial forces and dynamic impact loads.

This case introduces how Worldia customized PCBN inserts replace the traditional grinding process for finish turning the inner bore of wind turbine planetary gears, helping customers improve machining efficiency and reduce machining costs.

Solution Analysis

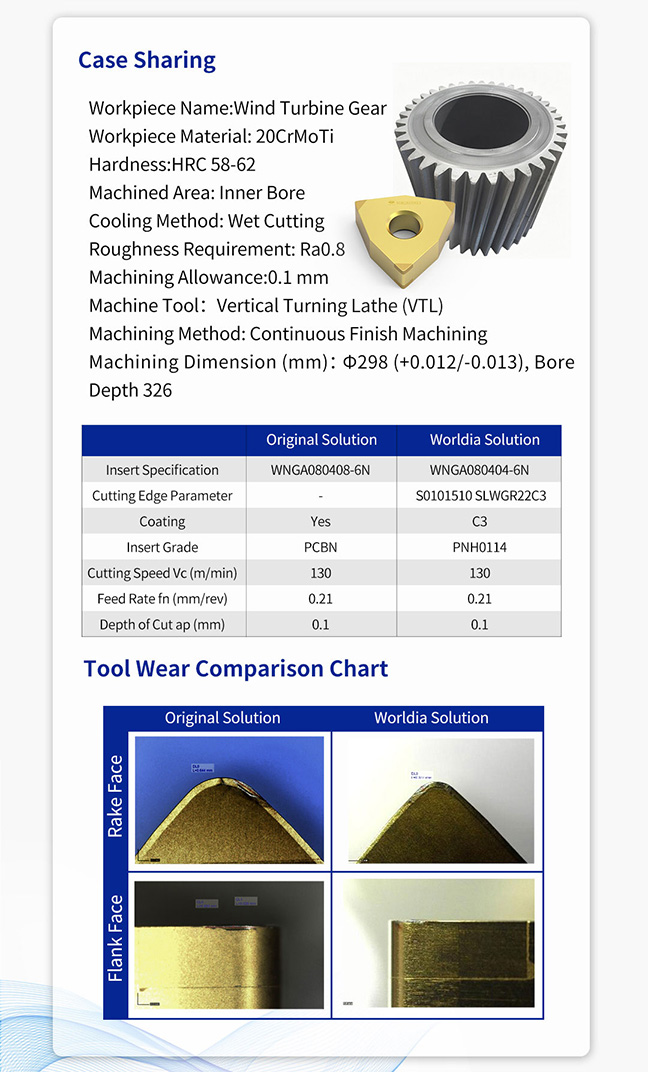

◎In this case, the wind turbine planetary gear features a large size (bore diameter Φ298 mm, bore depth 326 mm), strict tolerance requirements, surface roughness of Ra 0.8, and machining allowance of 0.1mm. According to the customer’s actual cutting conditions, Worldia adopted customized PCBN inserts. When machining the same part, the wear of both the rake face and flank face of the inserts was lower than that of the original tools used by the customer, and the surface roughness of the machined bore was better than that of the original solution. In other words, under the same cutting conditions, Worldia inserts offer superior wear resistance and longer tool life.

◎From the perspective of tool solution design, based on the material characteristics, machining allowance and requirements of the customer’s part, Worldia custom inserts are designed with a tool nose of smaller arc radius. Combined with the customer’s actual cutting conditions, the inserts adopt custom non-standard cutting edges and a wiper edge design, which is conducive to achieving higher surface machining quality. Meanwhile, the inserts are made of Worldia’s high-wear-resistance PNH0114 grade and coated with advanced C3 coating, effectively enhancing the high-temperature wear resistance and surface lubricity of the inserts.

◎Against the backdrop of the continuous growth of domestic and international raw material prices, Worldia custom tools can help customers optimize their existing tool solutions, improve machining efficiency, extend tool life, enhance machining quality and reduce machining costs.