Application Background

The development of humanoid robots is the result of the integration of multiple technologies such as machinery, materials, sensing, and artificial intelligence. As market applications continue to evolve, the machining of humanoid robot components will advance towards the direction of “standardization, mass production, and low cost”. The machining of some components will gradually overcome the limitations of traditional processing techniques, achieving greater machining flexibility and lower processing costs. For example, critical components like cycloidal gears and planetary gears (commonly made from hardened steel) in RV reducers, flexspline and circular spline in harmonic reducers, as well as planetary roller screws and nuts, typically use grinding as the final machining process in traditional manufacturing. Traditional grinding requires specialized equipment, which presents problems such as high processing costs and low machining efficiency.

Worldia’s customized PCBN hard turning and hard milling tools effectively address the pain points faced by traditional machining methods, such as poor flexibility, high costs for small-batch production, and low efficiency. They provide customers with exclusive, high-efficiency machining solutions.

Solution Analysis

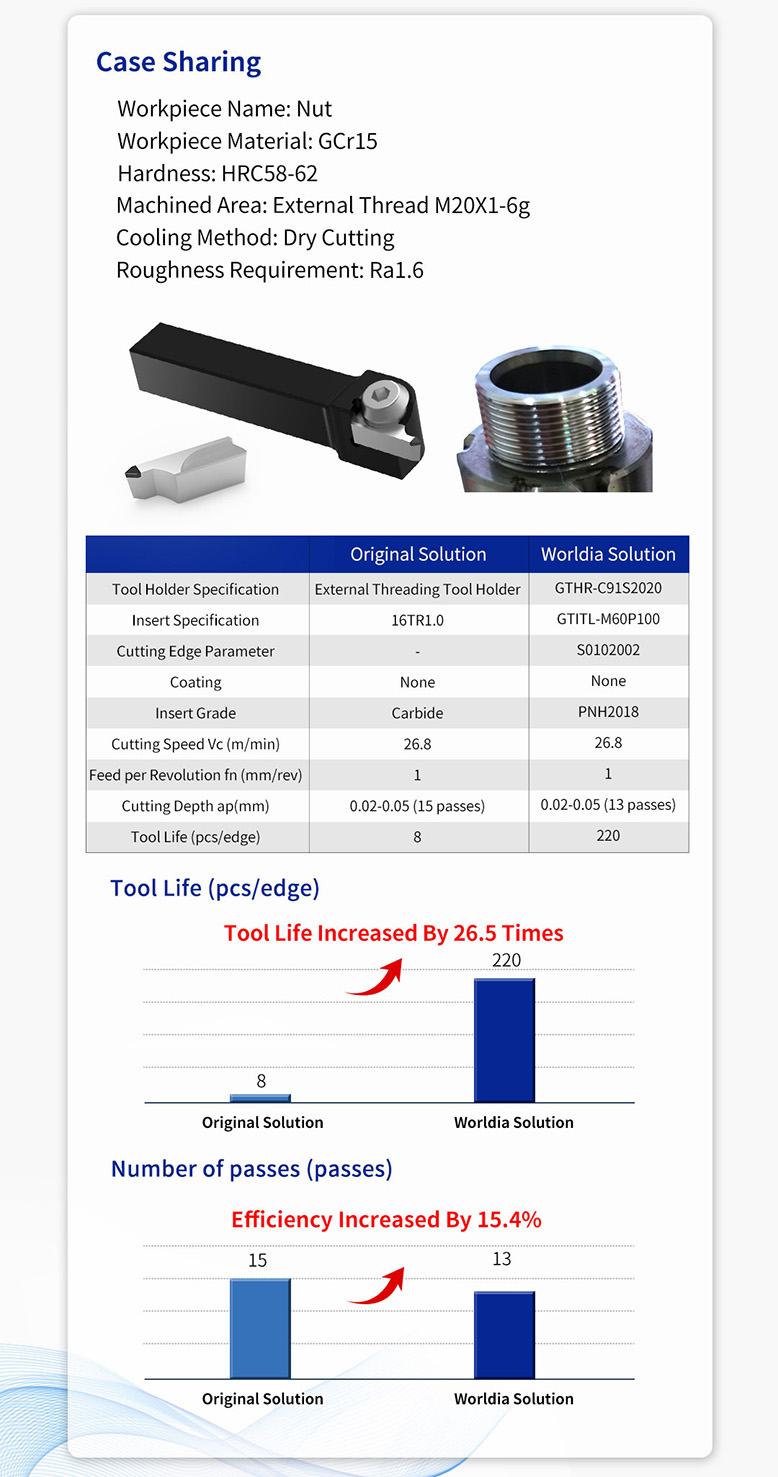

◎The material of the part in the case study is GCr15, which reaches a hardness of HRC58-62 after heat treatment. The Worldia tooling solution uses a customized PCBN external threading insert, paired with a standard toolholder with precise positioning and strong clamping rigidity.The insert is made of PNH2018 gradewith excellent toughness, and features a non-standard, custom-designed cutting edge specifically for this threading application.

◎Based on the customer’s actual machining conditions, the Worldia solution provides an exclusively customized PCBN external threading insert.Compared to the original tooling solution, the insert life has increased by 26.5 times,and machining efficiency has improved by 15.4%, eliminating the subsequent grinding process for the customer.

◎Worldia’s customized superhard tools provide exclusive solutions for humanoid robot component machining with longer tool life and higher machining efficiency, tailored to the specific characteristics of the customer’s parts and their actual machining conditions.