Application Background

In the machining industry, the cost of cutting tools accounts for a much smaller proportion of total production costs compared to machine tools and labor costs. Therefore, for machining enterprises, it is crucial to reduce per-unit processing costs and improve market competitiveness by process innovation, optimizing cycle time, and enhancing production efficiency.

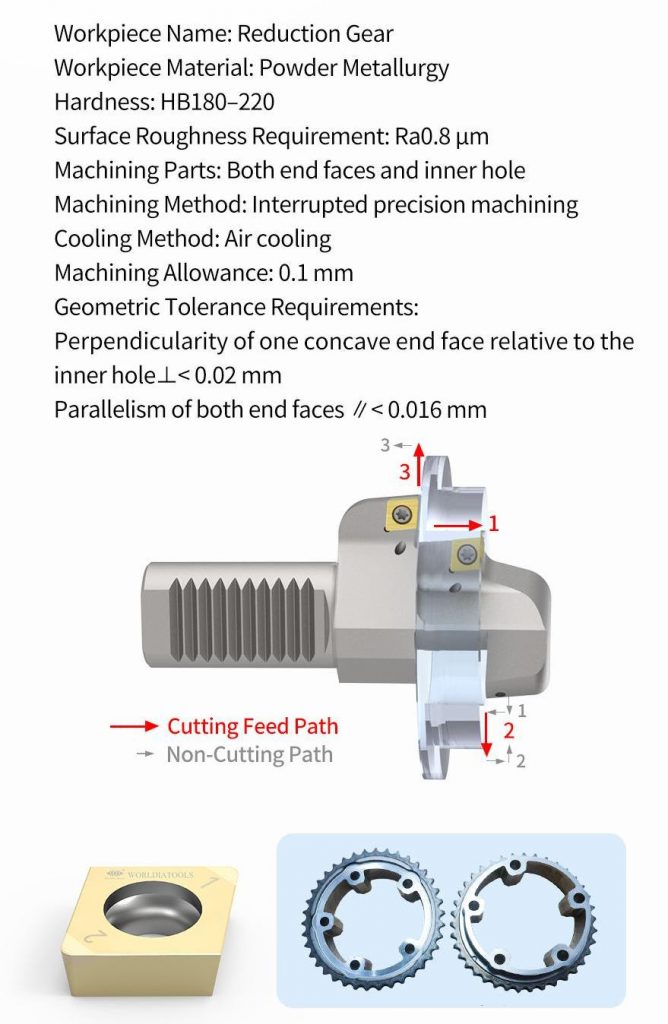

The application of composite tools enables the completion of multiple machining processes with a single tool. This not only improves machining efficiency and productivity but also avoids repeated positioning errors caused by multiple installations of the same part, thereby achieving higher machining precision.

Case Study

Case Analysis

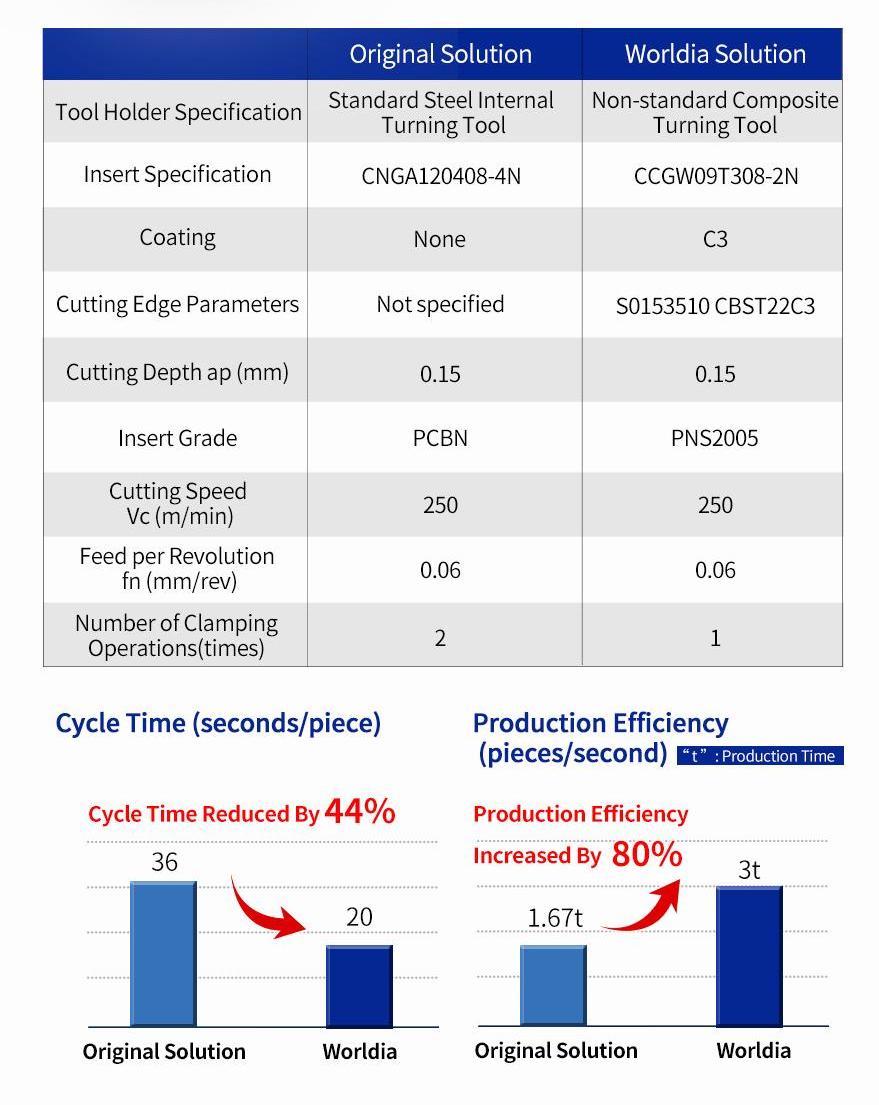

- By using a custom-designed non-standard composite turning tool, the Worldia solution enables the machining of both end faces and the inner hole in a single clamping operation. Compared with the original solution, it eliminates one clamping step, shortens cycle time by 44%, and increases production efficiency by 80%.

- The Worldia solution features a specially designed non-standard cutting edge, combined with a C3 coating that significantly enhances heat resistance, and the PNS2005 grade known for its excellent toughness and wear resistance,resulting in significantly longer tool life.

- The composite tool solution reduces the number of clamping operations and machine downtime, saving time costs for the customer. Additionally, machining both end faces and the inner hole in one clamping minimizes repositioning errors, thus achieving higher machining accuracy.

Data Source: Tool Test Report of Precision Tool Technology Department of Beijing Worldia Diamond Tools CO., Ltd.