| Model: | PCD milling insert for heavy cutting |

| Brand: | WORLDIA |

| Availability: | In stock,immediate despatch |

| Place of origin: | Beijing,China |

| Capacity(Monthly): | 20,000 |

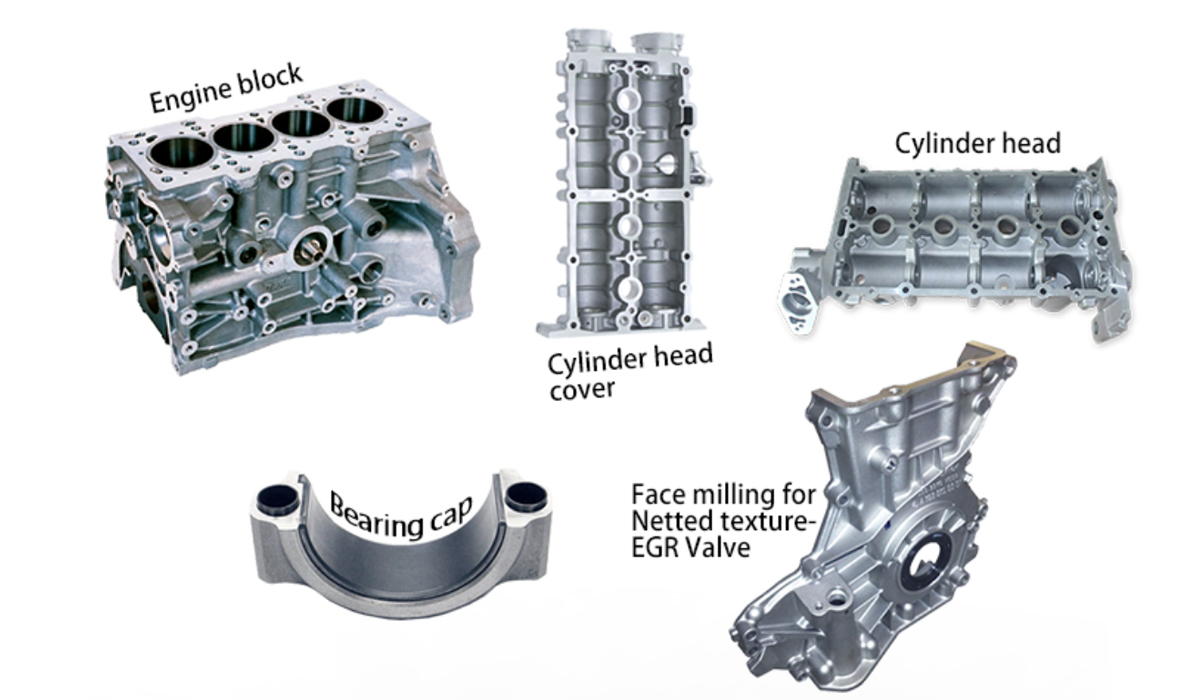

APPLICATIONS |

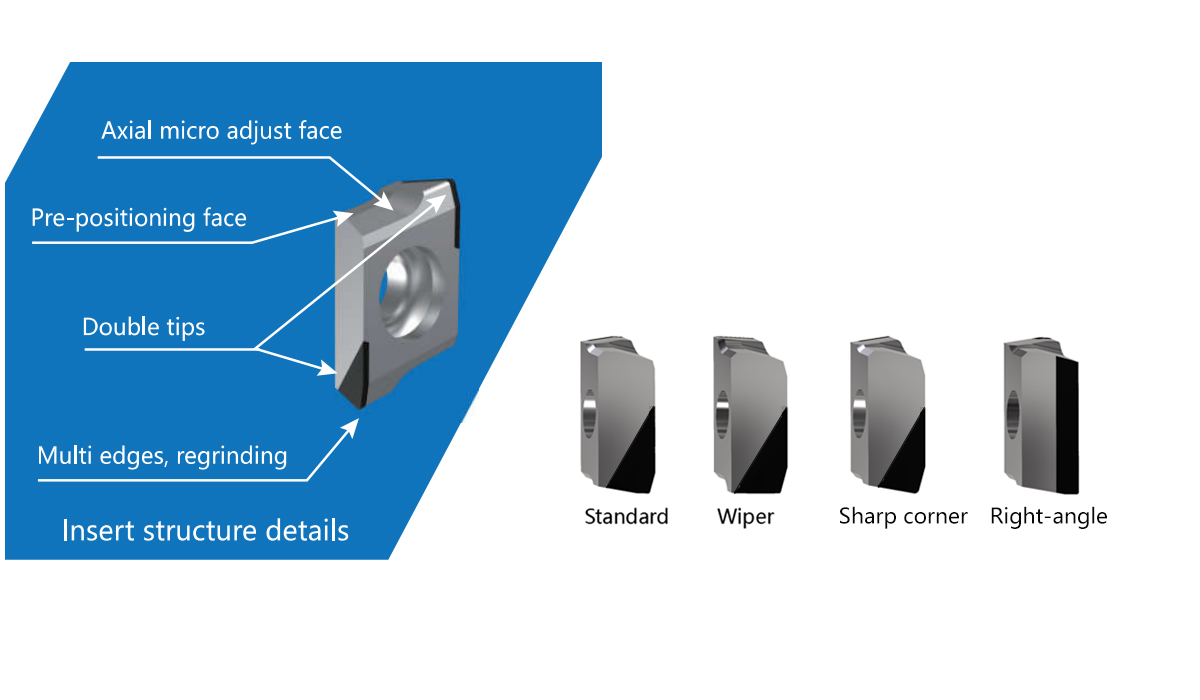

| WORLDIA PCD Milling Insert are designed by variety of Kr,could meet different application of end millling and shoulder milling.Two cutting edges design and retip service which could help customers reduce their cost.There are five types of cutting edge which can meet various application with different combinations.Realize both roughing and finishing in one tool. |

PRODUCT USAGE |

| According to grain size and features of diamond,four types of PCD material, i.e PD01E / PD10E / PD32E / CVDD are listed as below. |

| P | ||||

| M | ||||

| K | ||||

| N | ● | ● | ● | ● |

| S | ||||

| H | ||||

| Material | PD01E | PD10E | PD32E | CVDD |

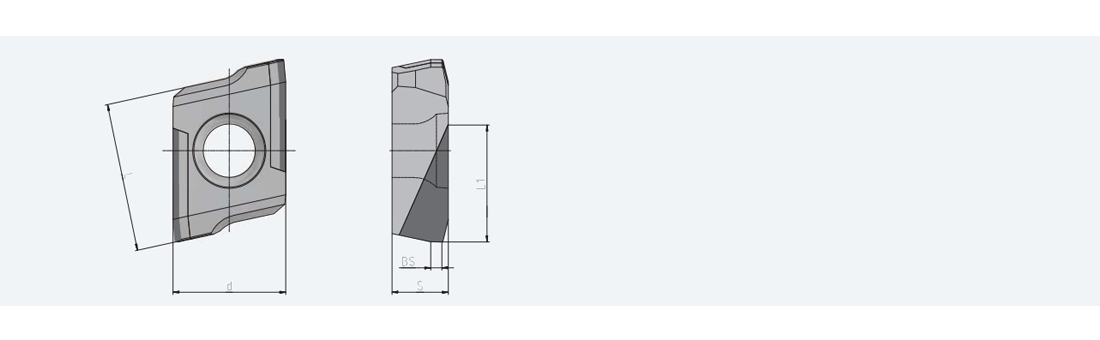

INSERT STRUCTURE DETAILS |

MATERIAL INTRODUCTION |

| Material | Grain size | Features | Application |

| PD01E | 1 | PD01E fine grain size PCD material(1μm) is suitble for finishing applications.Its high impart resistance and high abrasive resistance are no less than that of rough grade of PCD. | PD01E has excellent chip resistance is suitable for the roughing and interrupt cutting aluminium alloys.This grade is also commonly used for non-ferrous finishing applications.Other successful applications include machining of wood,MDF. |

| PD10E | 10 | PD10E is the universal grade in the market.It`s the first choice for many applications where a good balance of toughness and wear resistance are required. | This Grade is commonly used for non-ferrous finishing applications.Other successful applications include machining of wood,MDF.The machining of low-medium content silicon aluminium alloys,carbide,hard rubber,graphite and so on. |

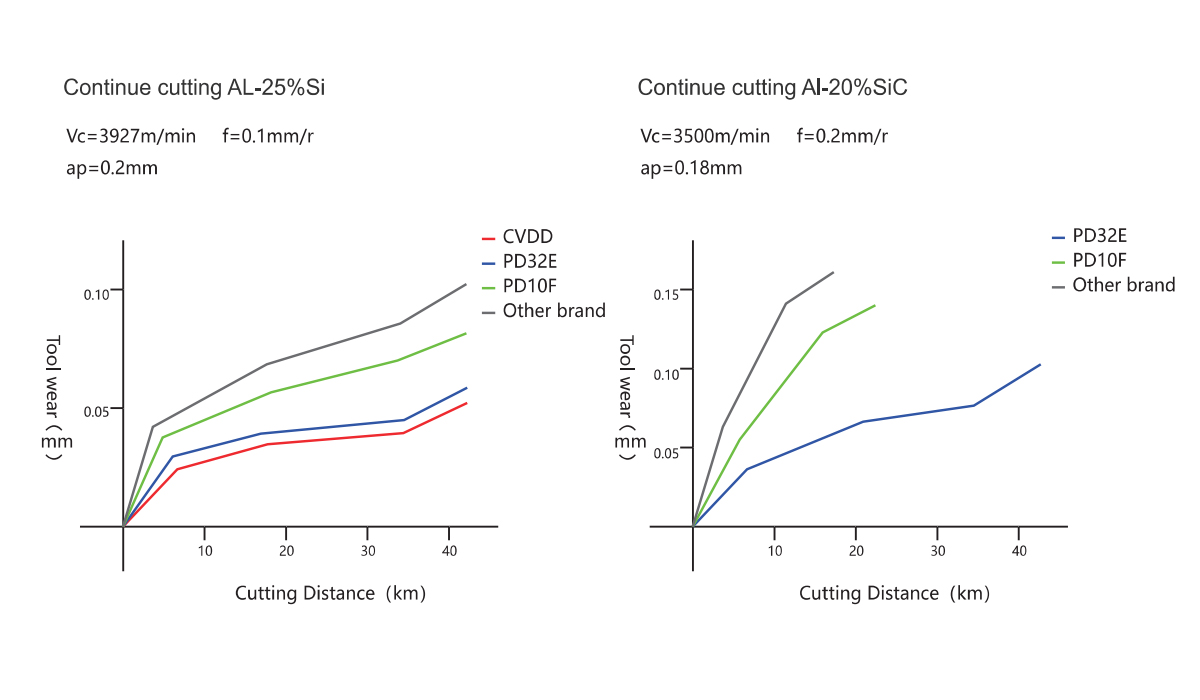

| PD32E | 2-30 | PD32E has a unique combination of wear resistance,edge strenth and edge quality.It contains a carefully sorted mix of micron diamond(Between 2 - 30 μm).The combination of these particle sizes and a specifically developed high pressure sintering process produces a structure with extreme abrasion resistance and good thermal stability. | Application areas include the machining of abrasive workpiece such as MMC,high silicon aluminium alloys as well as for the machining of carbide,hard rubber,graphite and other applications. |

| CVDD | - | CVDD is a pure carbon material without binder with extreme abrasion resistance and good thermal suitability.Due to its perfect cutting edge suitable fro appications where mirror finishes are required. | Application areas include the machining of abrasive workpiece such as MMC,high silicon aluminium alloys as well as for the machining of carbide,hard rubber,graphite and other applications. |

MATERIAL PERFORMANCE |

SPECIFICATIONS |

|

|

Cutter diameter |

Specification |

Cutting |

Dimensions |

N |

||||||

|

Type |

25-40 |

>40 |

Cutting Tips |

BS |

Ap Max |

Kr |

Re |

PD10E |

PD32E |

||

| Standard 75° | √ | BEHW1204EZTR1 R04CB08 | T1 | 1 | 1 | 7 | 75 | 0.4 | HC01763 | made to order | |

| √ | BEHW1204EZTR1B R04CB08 | T1 | 1 | 1 | 7 | 75 | 0.4 | HC02636 | made to order | ||

| Wiper 75° | √ | BEHW1204EZTR1-WG C03CB08 | T1 | 1 | 4 | 7 | 75 | - | HC03136 | made to order | |

| √ | BEHW1204EZTR1B-WG C03CB08 | T1 | 1 | 4 | 7 | 75 | - | HS05491 | made to order | ||

| Corner edge 75° | √ | BEHW1204EZTR1-PT R04CB08 | T1 | 1 | - | 7 | 75 | 0.4 | HC02508 | made to order | |

| √ | BEHW1204EZTR1B-PT R04CB08 | T1 | 1 | - | 7 | 75 | 0.4 | HC14492 | made to order | ||

| Universal 90° | √ | BEHW1204PZTR1-UW R04CB08 | T1 | 1 | 1.5 | 7 | 90 | 0.4 | HC04256 | made to order | |

| √ | BEHW1204PZTL1-UW R04CB08 | T1 | 1 | 1.5 | 7 | 90 | 0.4 | made to order | made to order | ||

| √ | BEHW1204PZTR1B-UW R04CB08 | T1 | 1 | 1.5 | 7 | 90 | 0.4 | HC04156 | made to order | ||

| Full Length 90° | √ | BEHW1204PZTR1 R04CB12 | T1 | 1 | 1 | 11 | 90 | 0.8 | HC02296 | made to order | |

| √ | BEHW1204PZTL1 R04CB12 | T1 | 1 | 1 | 11 | 90 | 0.8 | made to order | made to order | ||

| √ | BEHW1204PZTR1B R04CB12 | T1 | 1 | 1 | 11 | 90 | 0.8 | HC14044 | made to order | ||

PROCESSING CASES |