| Model: | TC Type |

| Brand: | Worldia |

| Availability: | Delivery time 15days |

| Place of origin: | Beijing,China |

| Capacity(Monthly): | 20,000PCS |

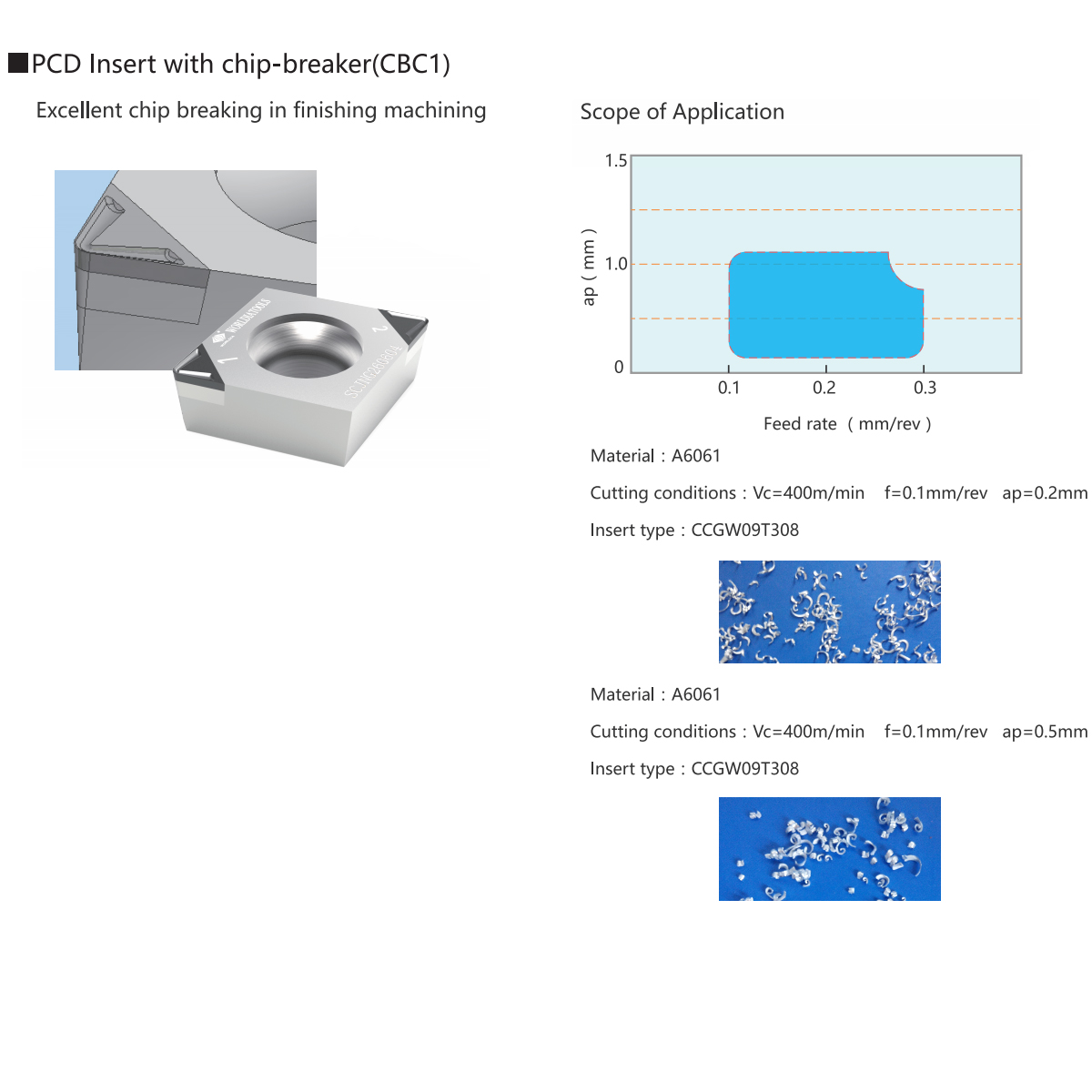

APPLICATIONS |

| PCD tools are limited to non-ferrous materials, such as high-silicon aluminium, metal matrix composites (MMC) and carbon fibre reinforced plastics (CFRP). PCD with flood coolant can also be used in titanium super-finishing applications. |

PRODUCT USAGE |

| According to grain size and features of diamond,four types of PCD material, i.e PD01E / PD10E / PD32E / CVDD are listed as below. |

| P | ||||

| M | ||||

| K | ||||

| N | ● | ● | ● | ● |

| S | ||||

| H | ||||

| Material | PD01E | PD10E | PD32E | CVDD |

MATERIAL INTRODUCTION |

| Material | Grain size | Features | Application |

| PD01E | 1 | PD01E fine grain size PCD material(1μm) is suitble for finishing applications.Its high impart resistance and high abrasive resistance are no less than that of rough grade of PCD. | PD01E has excellent chip resistance is suitable for the roughing and interrupt cutting aluminium alloys.This grade is also commonly used for non-ferrous finishing applications.Other successful applications include machining of wood,MDF. |

| PD10E | 10 | PD10E is the universal grade in the market.It`s the first choice for many applications where a good balance of toughness and wear resistance are required. | This Grade is commonly used for non-ferrous finishing applications.Other successful applications include machining of wood,MDF.The machining of low-medium content silicon aluminium alloys,carbide,hard rubber,graphite and so on. |

| PD32E | 2-30 | PD32E has a unique combination of wear resistance,edge strenth and edge quality.It contains a carefully sorted mix of micron diamond(Between 2 - 30 μm).The combination of these particle sizes and a specifically developed high pressure sintering process produces a structure with extreme abrasion resistance and good thermal stability. | Application areas include the machining of abrasive workpiece such as MMC,high silicon aluminium alloys as well as for the machining of carbide,hard rubber,graphite and other applications. |

| CVDD | - | CVDD is a pure carbon material without binder with extreme abrasion resistance and good thermal suitability.Due to its perfect cutting edge suitable fro appications where mirror finishes are required. | Application areas include the machining of abrasive workpiece such as MMC,high silicon aluminium alloys as well as for the machining of carbide,hard rubber,graphite and other applications. |

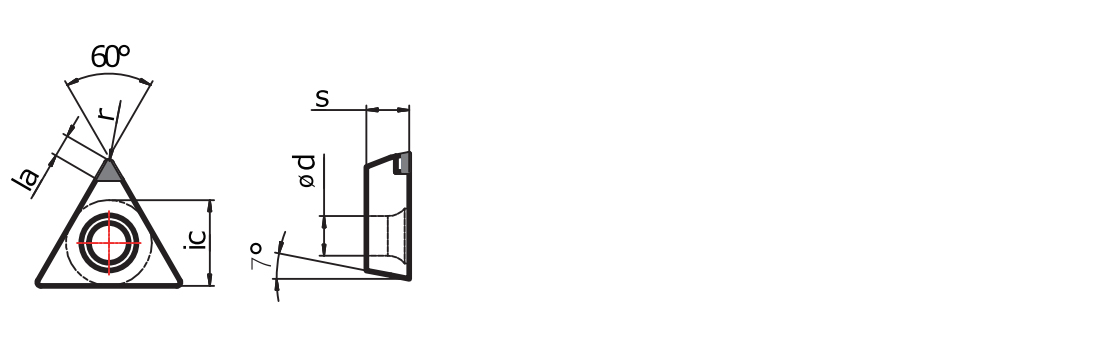

SPECIFICATIONS |

| Grade | ic | φd | s | r | la | ||||||

| ISO catalog number | ANSI catalog number | Tip Shape | PD01E | PD10E | PD32E | CVDD | mm | mm | mm | mm | mm |

| TCGW080202-1N P00P07 | TCGW(1.5)(1.5)(0.5)-1N P00P07 | CBCBC125S | ● | ● | ● | 4.76 | 2.4 | 2.38 | 0.2 | 2.5 | |

| TCGW080204-1N P00P07 | TCGW(1.5)(1.5)1-1N P00P07 | CBCBC125S | ● | ● | ● | 4.76 | 2.4 | 2.38 | 0.4 | 2.5 | |

| TCGW080202-1N P00P07 | TCGW(1.5)(1.5)(0.5)-1N P00P07 | SLCBC125S | ● | 4.76 | 2.4 | 2.38 | 0.2 | 2.5 | |||

| TCGW080204-1N P00P07 | TCGW(1.5)(1.5)1-1N P00P07 | SLCBC125S | ● | 4.76 | 2.4 | 2.38 | 0.4 | 2.5 | |||

| TCGW080202-3N P00P07 | TCGW(1.5)(1.5)(0.5)-3N P00P07 | CBCBC125S | ● | ● | ● | 4.76 | 2.4 | 2.38 | 0.2 | 2.5 | |

| TCGW080204-3N P00P07 | TCGW(1.5)(1.5)1-3N P00P07 | CBCBC125S | ● | ● | ● | 4.76 | 2.4 | 2.38 | 0.4 | 2.5 | |

| TCGW110302-1N P00P07 | TCGW22(0.5)-1N P00P07 | CBCBC125S | ● | ● | ● | 6.35 | 2.8 | 3.18 | 0.2 | 2.5 | |

| TCGW110304-1N P00P07 | TCGW22 1-1N P00P07 | CBCBC125S | ● | ● | ● | 6.35 | 2.8 | 3.18 | 0.4 | 2.5 | |

| TCGW110302-1N P00P07 | TCGW22(0.5)-1N P00P07 | SLCBC125S | ● | 6.35 | 2.8 | 3.18 | 0.2 | 2.5 | |||

| TCGW110304-1N P00P07 | TCGW22 1-1N P00P07 | SLCBC125S | ● | 6.35 | 2.8 | 3.18 | 0.4 | 2.5 | |||

| TCGW110302-3N P00P07 | TCGW22(0.5)-3N P00P07 | CBCBC125S | ● | ● | ● | 6.35 | 2.8 | 3.18 | 0.2 | 2.5 | |

| TCGW110304-3N P00P07 | TCGW22 1-3N P00P07 | CBCBC125S | ● | ● | ● | 6.35 | 2.8 | 3.18 | 0.4 | 2.5 | |

| TCGW160402-1N P00P07 | TCGW33(0.5)-1N P00P07 | CBCBC125S | ● | ● | ● | 9.525 | 4.4 | 4.76 | 0.2 | 2.5 | |

| TCGW160404-1N P00P07 | TCGW33 1-1N P00P07 | CBCBC125S | ● | ● | ● | 9.525 | 4.4 | 4.76 | 0.4 | 2.5 | |

| TCGW160408-1N P00P07 | TCGW33 2-1N P00P07 | CBCBC125S | ● | ● | ● | 9.525 | 4.4 | 4.76 | 0.8 | 2.5 | |

| TCGW160402-1N P00P07 | TCGW33(0.5)-1N P00P07 | SLCBC125S | ● | 9.525 | 4.4 | 4.76 | 0.2 | 2.5 | |||

| TCGW160404-1N P00P07 | TCGW33 1-1N P00P07 | SLCBC125S | ● | 9.525 | 4.4 | 4.76 | 0.4 | 2.5 | |||

| TCGW160408-1N P00P07 | TCGW33 2-1N P00P07 | SLCBC125S | ● | 9.525 | 4.4 | 4.76 | 0.8 | 2.5 | |||

| TCGW160402-3N P00P07 | TCGW33(0.5)-3N P00P07 | CBCBC125S | ● | ● | ● | 9.525 | 4.4 | 4.76 | 0.2 | 2.5 | |

| TCGW160404-3N P00P07 | TCGW33 1-3N P00P07 | CBCBC125S | ● | ● | ● | 9.525 | 4.4 | 4.76 | 0.4 | 2.5 | |

| TCGW160408-3N P00P07 | TCGW33 2-3N P00P07 | CBCBC125S | ● | ● | ● | 9.525 | 4.4 | 4.76 | 0.8 | 2.5 |