The CV-Joint (Constant Velocity Joint) is a critical component of the ball cage steering mechanism. It connects two non-collinear shafts and enables them to rotate at the same angular velocity while transmitting power. Its fundamental principle is to achieve constant velocity power transmission between shafts with an angular offset. Typically, the front wheels are responsible for both driving and steering, requiring a solution capable of handling large angular deflections. The CV-Joint excels at meeting this need, overcoming the issue of non-uniform velocity inherent in conventional cross-axis universal joints, making it particularly suitable for use in steering drive axles.

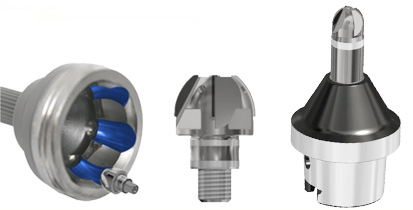

The outer race shell is a key component of the CV-Joint. This case study demonstrates how Worldia’s CV-Joint ball track milling cutter effectively processes the bell-shaped housing, significantly improving machining tool life.

| Workpiece Information | |

| Workpiece Name | Outer Race Shell |

| Cooling Method | Air cooling |

| Material | SAE 1050M |

| Processing Part | Outer Raceway |

| Hardness | HRC58-62 |

| Surface Roughness Requirement | Ra0.8 |

| Original Solution | Worldia Solution | |

| Tool Model | HQM-19.844 | 19.844HS14 |

| Coating | Uncoated | Uncoated |

| Cutting Depth (ap) | 0.2/0.1 mm | 0.2/0.1 mm |

| Cutting Speed (Vc) | 170 m/min | 170 m/min |

| Feed per Revolution (fn) | 0.08 mm/r | 0.08 mm/r |

| Inner Raceway Processing Improvement | Original Solution | Worldia Solution |

| Tool Life | 500 pcs/edge | 700 pcs/edge (+40%) |

1.Milling Instead of Grinding

Replacing traditional grinding processes with milling reduces complex grinding operations, helping customers lower processing costs.

2.High Processing Efficiency

Custom-designed tools tailored to part dimensions ensure high efficiency. The tool features four cutting edges for one-pass shaping, significantly enhancing productivity.

3.Patented Modular Interface

The interface between the tool head and body uses a patented special positioning method, ensuring simple and reliable operation.

(Patent No.: ZL 2022 2 1346858.X)

4.Replaceable PCBN Tool Heads

The replaceable PCBN (polycrystalline cubic boron nitride) tool heads are regrindable, helping customers reduce tool costs.

5.Standardized Design

Frequently used specifications are standardized, ensuring reliable processes and timely delivery.

6.Internal Cooling Design

The tool incorporates a uniquely designed cooling channel, ensuring effective chip evacuation and cooling.

Mit nur einem Klick gelangen Sie zum nächsten Thema.